Fishmeal processing machinery mainly uses fish with low economic value, fish production and processing waste or some crustaceans and cephalopods as raw materials to produce and process into fishmeal machinery and equipment. In addition to being used for the production of fish meal for feed, if the raw materials are fresh and the facilities meet hygienic conditions, it can also be used for the production of edible fish meal. Industrial fishmeal processing machinery has been produced in the 1920s. Complete sets of fishmeal equipment can be roughly divided into two categories: dry processing machinery and wet processing machinery due to different processing techniques. In the 1960s, centrifugal wet processing machinery was produced in the latter category.

The structure of this kind of machinery is simple and clear, and the facilities are less, and it is suitable for the production and processing of low-fat raw materials. However, due to the high temperature of the raw materials in the steam dryer, the oil is easily oxidized, and the quality of the obtained fish oil is poor. It is only used in a few areas today.

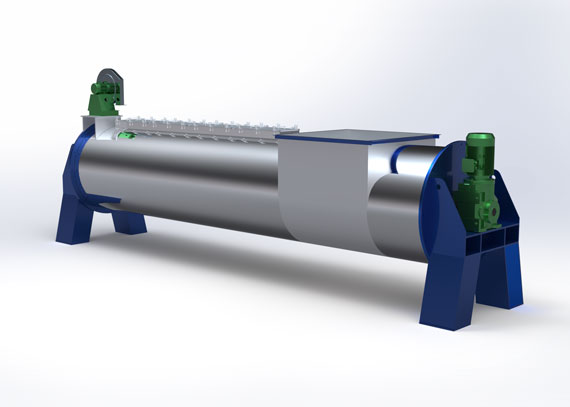

Wet processing machinery is mainly composed of chopper, digester, press, fish oil separator, juice concentrator, dryer, pulverizer, etc. The raw materials are first cut into small pieces by the chopper, cooked according to the cooker, and most of the water and fish oil are squeezed out by the press, and the juice left after the fish oil is separated from the fish oil by the fish oil separator The water-soluble protein) is concentrated in the evaporator, mixed with the pressed cake and sent to the dryer for drying; and then crushed into powder by the pulverizer.

At this stage, with the advancement of technology, the press is progressing towards the perspective of specialization, automation, energy saving and pollution-free, and improving the production and processing efficiency and quality of fishmeal is a kind of crucial fishmeal processing equipment.

The purpose of using fishmeal production equipment is to keep the fishmeal dry as soon as possible. The complete set of fishmeal facilities has certain advantages in the application process, such as: high degree of automation and good product quality. Air-flow drying materials are all carried out in the pipeline, and the drying time is very short, so it can be automated, the products are not in contact with the outside world, the pollution is small, and the quality is good.