What is a fishmeal screw press?

The fish meal screw press is mainly used for the degreasing and dehydration of fish meal after cooking. It is also suitable for degreasing and dehydrating high-humidity materials such as steamed fish and shrimp scraps, wet feathers, animal bones and meat after chemical sterilization, and kitchen waste.

Types of fish meal screw presses

There are two types of fishmeal presses: single screw and twin screw. The single-screw press is similar to the screw press in the dry-process machinery, but its screw changes both the bottom diameter and the pitch to increase the compression ratio. The twin-screw press has two screws with variable bottom diameter, variable pitch and opposite rotation, which can prevent the failure of pressing due to the rotation of the material and the screw together.

A twin-screw press is generally recommended. A good press can generally control the water content below 50%.

How a fishmeal screw press works

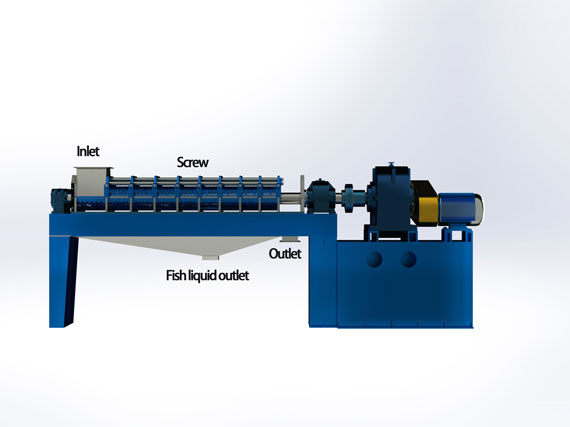

The fish meal screw press is mainly composed of frame, transmission system, feeding part, juicing part, hydraulic system, shield and electrical control part.

The fish feed is rotated and advanced in the press cavity by the conical screw. The taper of the screw makes the volume of the material gradually shrink during the process of traveling, and bears an increasing extrusion force, so as to extrude the liquid in it. The press chamber has a complete set of screen structures to ensure solids retention and filtration of liquids.

Features of fishmeal screw press

It is used for pressing and dewatering of various high-moisture materials and degreasing of animal materials.

Adjust the spindle speed according to different materials, so that the material can be pressed.

The fully enclosed structure ensures that there is no leakage of liquid and steam during the production process, which is convenient for the cleaning of the workplace.

At present, with the development of technology, the press is developing in the direction of specialization, automation, energy saving and pollution-free, and it is one of the important fishmeal processing equipment to improve the processing efficiency and quality of fishmeal.

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fishmeal and fish oil equipment production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fishmeal industry.

Based on years of R&D and

production experience of fishmeal equipment production lines, Feeds

Machinery has launched the Fishmeal Process (FMP), a wet-process

fishmeal production process, suitable for the production of fishmeal

with raw material capacity up to 15 tons/hour and above. The produced

fishmeal has better quality, high digestibility, low energy consumption

and simple operation. If a complete fishmeal and fish oil production and

processing system is adopted, the production capacity can be increased

by 5% (the digestibility is increased by 3%), and the whole process can

be achieved without pollution.