As we all know, fish meal plant is also called fishmeal dryer. It is composed of a horizontal shell and a rotating shaft containing steam heating. A heating coil is welded on the shaft, and a pushing plate is installed on the disc.

The working efficiency of the fishmeal facility is high. , It can not only heat the fish meal, but also move the heated fish meal along the direction of the powder outlet. The steam dividing device of the internal structure of the rotating shaft can make the steam evenly spread to each heating disc, and the steam and condensed water are separated from each other. The flow in the coils on both sides of the disc keeps the heating disc at a constant high temperature.

The processing equipment of fishmeal facilities is mainly classified as follows:

Fish meal production system

Feeding pit,

Screw conveyor

Cooking machine

Filtrate screw conveyor

Twin screw press

Dryer

Powder auger

Cooling Auger

Cylinder sieve

Crusher

Powder storage bin.

Liquid phase separation and fish oil processing equipment:

Mud pump

Screw pump

Gear pump

Centrifugal pump

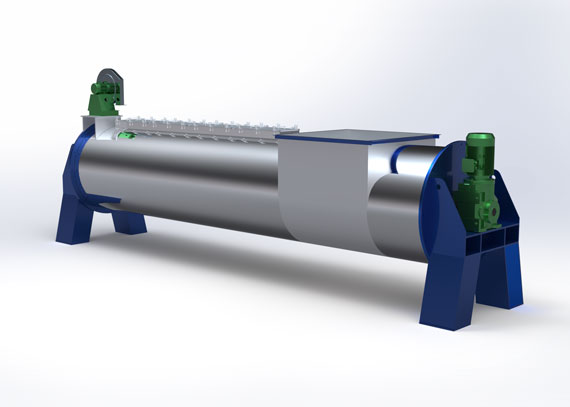

Horizontal spiral centrifugal decanter

Disc centrifugal oil-water separator

Protein concentration facilities:

Horizontal centrifugal decanter

Falling film vacuum double-effect concentration device

Jet vacuum pump.

Environmental protection system facilities:

Water washing tower (forest spray deodorization tower),

Induced draft fan.

The classification of fishmeal equipment is introduced here. If you have any other related questions, please consult and answer them through the Internet or telephone.