Before introducing the disc sludge dryer, let's first understand the sludge dryer:

1.What is a sludge dryer

The sludge dryer is a device that dehydrates and dries wet sludge directly or indirectly. The dried sludge can be used for agriculture, fuel, incineration or sent to landfill.

2. What is a disc sludge dryer

The disc sludge dryer is also known as rotary sludge dryer. Disc sludge dryer is a kind of indirect heating of sludge through medium such as steam or heat transfer oil, so as to achieve dehydration and drying reduction of sludge as device for the purpose. It consists of a rotating main shaft and a stationary housing.

Dozens of heating discs are installed on the rotating spindle, and the discs are closely arranged, providing a huge heat exchange area for drying materials. Saturated steam (usually 6kg) enters from a section of the rotating shaft through the rotary joint, and then enters each disc evenly through the steam separation device on the main shaft. During the rotation of the disc, the steam transfers heat to the material. The material continuously evaporates water after absorbing heat outside the disc. The condensed water condensed by the steam is collected into the condensed water chamber of the main shaft through the water channel, and then discharged from the other end of the rotating shaft through the siphon.

3. Application scenarios of disc sludge dryer

Widely used in the drying of industrial sludge and domestic sludge, industrial sludge includes: petrochemical sludge, paper sludge, printing and dyeing sludge, leather sludge, electroplating sludge, petrochemical sludge, coal washing sludge, waterworks Sludge, pickling sludge, medicinal residue sludge, construction sludge, pulp sludge, oily sludge, etc.; domestic sludge includes: municipal sludge, sewage sludge, activated sludge, pool sludge, silt, mud, mud etc. It is also suitable for pulp sludge bio-fermentation slag and fish meal processing, starch processing, distiller's grains and other feed or food drying.

4. The working principle of the disc sludge dryer

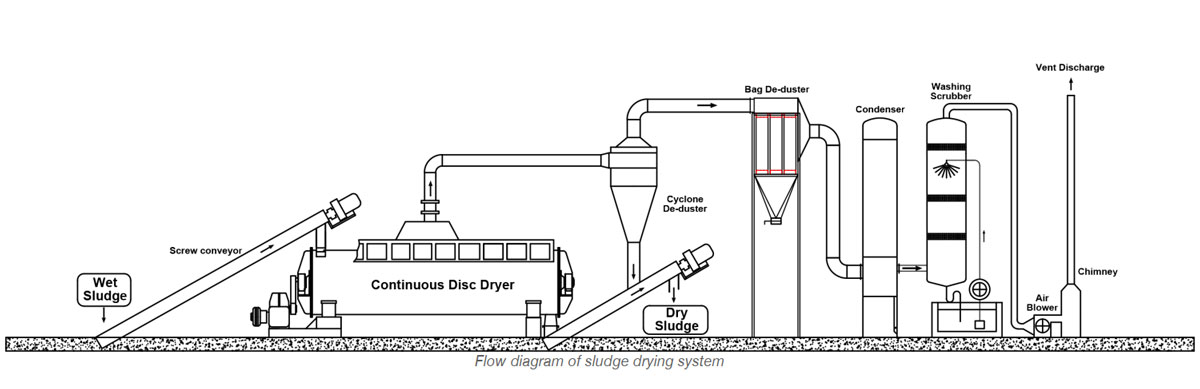

The complete sludge drying system includes screw conveyor, disc dryer, dust collector, steam condenser and deodorization tower. Wet sludge from screw press sludge dewaterers typically contains 70-80% moisture. The sludge is continuously fed into the disc dryer by means of a screw conveyor, where it will be heated. The moisture material inside is vaporized and sucked away by the blower. The exhaust gas discharged from the dryer enters the steam condenser after being dedusted. The condenser turns most of the steam into condensed water. The exhaust gas is deodorized by the biological deodorization tower, and then discharged through the chimney. The discharged dry sludge usually also contains 20-30% moisture.

As a professional dryer manufacturer, Feeds Machinery has rich experience in the design and manufacture of sludge treatment equipment. What's more, Feeds Machinery can provide a total solution for sludge treatment with a rich product line and strong manufacturing and assembly capabilities.

Therefore, if you have any needs for sludge treatment, please feel free to contact Feeds Machinery. You can find our contact information on the official website of Feeds Machinery at www.feedsmachinery.com.