Fish meal is a high-protein feed that uses one or more kinds of fish or fish scraps (fish head, tail, fin, internal organs, etc.) At the beginning of the 21st century, the world's total output was about 7 million tons. The countries with the largest output were Chile, Peru, Japan, and the United States. At the same time, Norway, Denmark, South Africa, Iceland and Thailand were also major fishmeal producers. Among them, Chile and Peru have the highest output, with the highest annual output reaching more than 1.3 million tons (1989) and more than 1.2 million tons (1990) respectively, and their exports account for about 70% of the total trade volume. China's fishmeal industry started late, with an annual output of about 100,000 tons, and most of them are concentrated in coastal provinces such as Shandong, Zhejiang, Guangdong, and Fujian. China uses a relatively high amount of fishmeal, with an annual consumption of nearly 1 million tons, and an annual import of about 800,000 tons. Most of the imported fishmeal comes from Peru.

1.What is a fish meal dryer

In short, fish meal dryer is a kind of equipment that obtains coarse fish meal by drying the solid after cooking in fish meal production through the heat source generally steam.

Fish meal dryers generally consist of a rotating main shaft and a stationary shell.

Dozens of heating discs are installed on the spindle rotating at the rated speed, and the discs are closely arranged, providing a huge heat exchange area for drying materials. Saturated steam (usually 6kg) enters from a section of the rotating shaft through the rotary joint, and then enters each disc evenly through the steam separation device on the main shaft. During the rotation of the disc, the steam transfers heat to the material. The material continuously evaporates water after absorbing heat outside the disc. The condensed water condensed by the steam is collected into the condensed water chamber of the main shaft through the water channel, and then discharged from the other end of the rotating shaft through the siphon.

2.The working principle of fish meal dryer

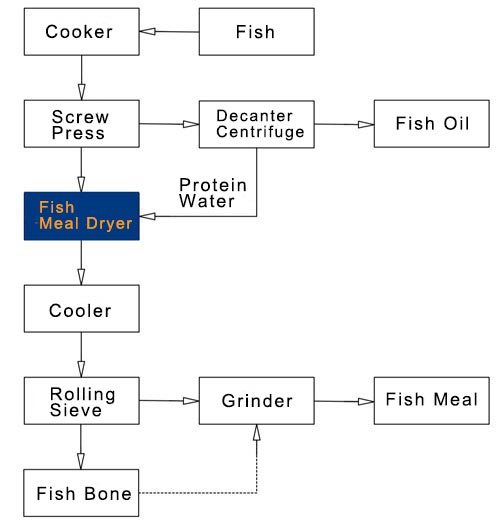

The processing of fish meal generally goes through the processes of cooking, pressing, separation, drying, grinding, etc. Generally, one or more kinds of fish are used as raw materials for processing.

Raw fish or fish steaks and leftovers enter the hopper after iron removal by the magnetic separation equipment, and then are continuously fed into the cooking machine through the screw conveyor. After the material is cooked, it directly enters the press. After the twin-screw pressing, the pressed juice enters the juice pool, the pressed cake enters the dryer, and the protein water is concentrated and added to the dryer for drying.

After initial precipitation, the juice of the pressing liquid is sent to the heating tank, heated to a certain temperature, and then sent to the three-phase decanter centrifuge to separate the fish residue and fish liquid, the fish residue is returned to the dryer, and the fish liquid is sent to the dish The oil-water separation is carried out by a type separator, and the separated fish oil is reprocessed to obtain the finished fish oil.

Feeds Machinery provides the design, manufacture, installation, commissioning and after-sales maintenance of a complete set of fishmeal and fish oil production lines, and provides customers with complete sewage and waste gas treatment solutions to achieve pollution-free fishmeal industry.

Based on years of experience in the research and development and production of fishmeal processing equipment, Feeds Machinery launched the FM series fishmeal dryer, which is different from the traditional fishmeal dryer and has a unique spindle design. The main shaft does not expose the welding seam, avoids the welding seam directly contacting the material, and prevents the material from wearing and corroding the welding seam, thus greatly prolonging the service life of the dryer.

FM series fish meal dryer can be manufactured into various sizes and specifications according to the demand of output and under the conditions of transportation. The dryer can also be made of carbon steel Q345, stainless steel 304, 316L or bidirectional stainless steel according to the nature of the material.