Sludge dryer is a drying equipment that dries various activated organic sludge and then produces sludge organic fertilizer. The drying of the sludge allows the sludge to be used in agriculture, fuel, incineration and even landfill reduction.

1.Why do we need to dry sludge?

Before understanding what sludge dryer is, we must first consider a question, that is why we need to dry sludge, and what is the purpose of drying sludge. Sludge is not the sludge in the ditch or the sludge in the fields in our lives, but the industrial wastewater sludge and municipal sludge produced by industrial production.

With the development of my country's modern industry, the output of sludge has also increased, and sludge treatment and disposal has become a new difficulty and challenge in comprehensive environmental management. Sludge dumping and landfill treatment methods have caused serious secondary pollution of water sources and land, waste of solid waste resources, and waste of land resources. During the 12th Five-Year Plan period, my country will invest more than 500 billion yuan for solid waste treatment, of which sludge Governance is exemplified as a key governance category. Among them, the sludge dryer plays a great role in the drying of sludge.

Environmental protection requirements, different regions have different requirements for sludge disposal. For example, in some regions, the moisture content of sludge is higher than 70% and cannot be directly treated (qualified units are recycled and incinerated, which refers to hazardous waste or non-reusable sludge).

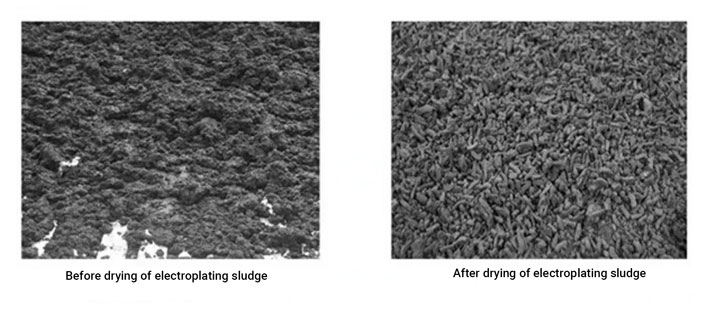

The disposal cost is high. Industrial sludge, chemical sludge, electroplating sludge, etc. are all hazardous waste sludge, and the disposal cost ranges from 1,800 to 9,000 per ton. And many large enterprises produce tens of tons or even hundreds of tons of sludge every day.

The disposal capacity of the incineration disposal unit is limited. The environmental protection disposal unit has a fixed annual disposal amount due to mechanical equipment, and cannot collect an unlimited amount of sludge. However, the amount of sludge produced by the enterprise is far greater than the amount that can be disposed of, so it is necessary to achieve the purpose of weight reduction and weight reduction through drying.

2. Three main values of sludge drying

1.Removing the moisture in the sludge can reduce the volume of the sludge and reduce the cost of sludge treatment.

2.The physical and chemical properties of the sludge are stabilized, and further degradation will not occur during the sludge disposal process to avoid secondary pollution.

3.Use sludge for aerobic composting, incineration, resource reuse, or even landfill

3. What is a sludge dryer

Simply put, the sludge dryer is a sludge drying equipment used to evaporate the moisture in the sludge. There are mainly two types of indirect evaporation and direct evaporation.

According to different sludge drying methods, sludge dryers can be roughly divided into the following three types:

Direct drying

Indirect drying

Solar drying

Direct drying equipment mainly includes:

Belt conveyor sludge dryer

Fluidized Bed Sludge Dryer

Drum Sludge Dryer

Flash Sludge Dryer

Direct drying is the most common drying method for sludge treatment in sewage treatment. The sludge is in direct contact with the heat source, thereby evaporating the water in the sludge. Since the process requires a large amount of heat source consumption, the heat source is usually recovered during the evaporation process to save energy.

Indirect drying, also known as conduction dryer, uses conduction to transfer the heat of the heat source to the wet material through the metal partition, and the generated water vapor can be removed by vacuum suction, a small amount of steam or separate low-temperature condensation recovery. This type of dryer does not use drying medium, has high thermal efficiency, and does not pollute the product, but the drying capacity is limited by the heat transfer area of the metal wall, the structure is also complex, and it often operates in a vacuum environment.

Indirect drying equipment mainly includes:

Paddle Sludge Dryer

Disc Sludge Dryer

Membrane sludge dryer

Solar drying is a drying equipment that uses the heat energy of solar radiation to evaporate the moisture in the wet material.

As a professional dryer manufacturer, Feeds Machinery has rich experience in the design and manufacture of drying treatment equipment. What's more, Feeds Machinery can provide a total solution for drying processing with a rich product line and strong manufacturing and assembly capabilities.

Therefore, if you have any needs for drying treatment, please feel free to contact Feeds Machinery. You can find our contact information on our website of www.feedsmachinery.com.