We all know that the quality of industrial wastewater is mainly inseparable from the production of factories. Different industries use different raw materials, so the resulting wastewater quality and cost are also different. Below we will focus on "How much cost to treat a ton of industrial wastewater" for a more detailed answer.

The types of industrial sewage treatment are divided into petroleum industry, chemical industry, textile industry, pharmaceutical industry, catering industry, beverage industry, starch industry, paper industry, etc.

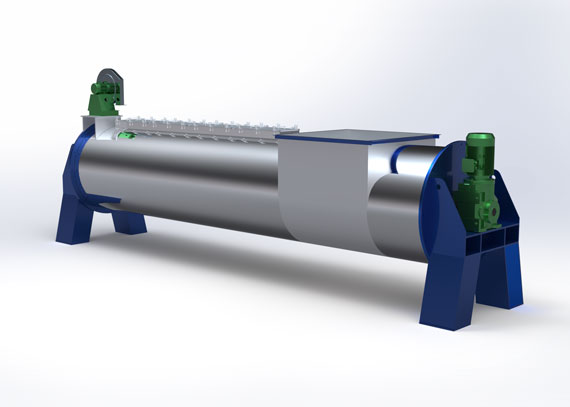

The industrial sewage treatment equipment uses different sewage treatment processes according to the composition of the wastewater. The equipment commonly used in the industry includes integrated sewage treatment equipment, chemical wastewater treatment equipment, buried sewage treatment equipment, evaporators, seawater desalination equipment, organic Wastewater treatment of waste water, landfill leachate treatment, etc.

Industrial wastewater generally contains suspended solids, hexavalent chromium, lead, oxygen demand, sulfide, petroleum, cadmium, cod, ammonia nitrogen, etc.

After treatment, industrial wastewater can be recycled and reused or directly discharged after treatment. For example, electroplating wastewater can be evaporated and crystallized to recover some of the metals contained in the electroplating solution. After treatment, papermaking water can be recycled for irrigation and road sprinkler Wait.

wastewater treatment equipment, the wastewater treatment process used, the quality of sewage, the quality of effluent, and the amount of water treated every day are directly linked to the cost.

FEEDSMACHINERY can customize different water treatment processes and equipment of different sizes according to the user's enterprise scale, industrial wastewater type, and effluent quality requirements. We have always put the user's interests first, extending the service life of the equipment and reducing the equipment. operating costs, etc.