The price of a complete set of fishmeal ...

Biotrickling Filter

Biotrickling filter is a device that converts organic matter into carbon dioxide, water and heat using the principle of adsorption and decomposition of microorganisms.

Exhaust gas treatment technology that deodorizes the molecular structure of odor by using the microbial membrane on the biological filter filler.

Parameters

Core Parameters| Capacity | 0-20000 m3/h |

|---|---|

| Material | FRP/PPH |

| Packing Media | Biofiller, Coconut Bark, Pine Bark, Adsorbed Carbon, Lava Rocks |

Features

Strong application adaptability: By adding thermal insulation layer and cooling system, biological trickling filtration can be applied to various environments and temperatures.

Application: Suitable for a variety of inorganic and organic odors, including NH3, H2S, mercaptans, thioethers, amines, alcohols, aldehydes, ketones, etc.

Stink gas.The process is simple and the operating conditions are low: biodegradation can be carried out at room temperature.

Low equipment investment and low operating cost: The biological trickling filtration process only needs a biological box and a circulating pump to start working.Low investment and almost no additional operating costs.

Secondary pollution, pollutants are degraded by microorganisms into non-toxic and harmless small molecular substances such as CO2, H2O, inorganic salts, etc.

Optimize the growth environment of microorganisms, promote the growth of microorganisms, and improve the efficiency of biodegradation: by adding and replacing nutrient solutions, adjust the

The pH value and temperature of the microbial growth environment can be controlled, so that the metabolism of the microorganism can be kept active, so as to maximize the biological

Filtration efficiency. The tunability of the growth environment of microorganisms is the distinguishing feature of biological trickling filtration from other biological filtration technologies.

Application

The biotrickling filter has a good deodorizing effect for those odors with low concentration of pollutants, large quantities and good biochemical properties. Taking advantage of the low cost and good controllability of biological trickling filtration, it has been successfully applied in many industries:

Feed processing plants (fish meal processing, meat and bone meal processing)

Processing plants (slaughterhouses, intestines)

Fertilizer plant

Brewery/Fermentation Room

Food Processing Plant

Industrial, municipal sewage station/pumping station

Sludge drying

Biopharmaceutical Room

Working Principle

Biotrickling filter for waste gas streams containing VOCs and odorous compounds is more cost effective and environmental-friendly than conventional air pollution control technologies.

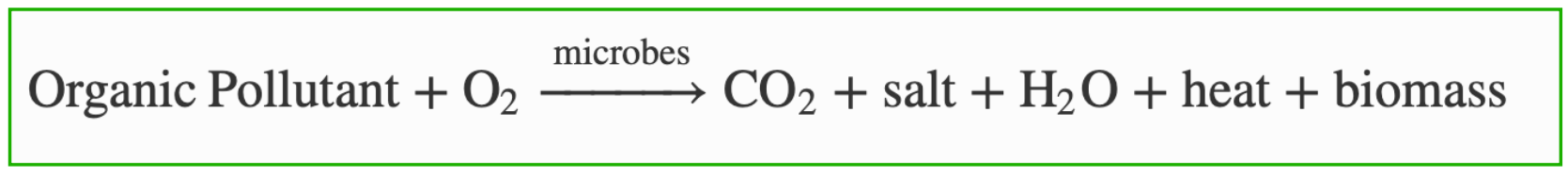

In a biofilter, the pollutants are biologically degraded by aerobic microorganisms to stable end products like CO2, H2O, sulfate, microbial biomass, etc.

The simple equation for microbial degradation of odor is as follows:

Cases

3000 m3/h Deodorization in Pump Station

5000 m3/h Deodorization in Casing Workshop

10000 m3/h Odour Control in Fish Meal Plant

Related Articles

How do fish oil refining equipment manuf...

The fish meal dryer is composed of a she...

Fish meal screw press mainly used for de...

What are the maintenance work of waste g...