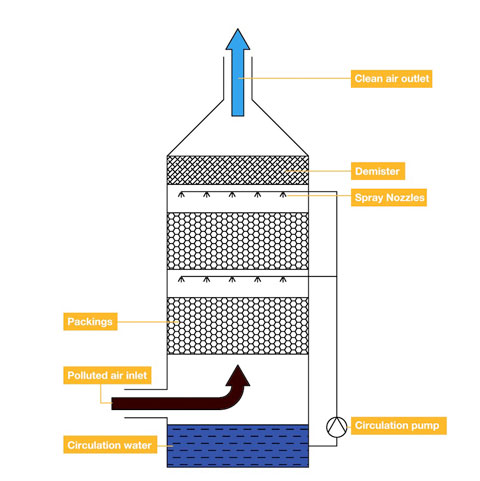

Wet Scrubber

As a commonly used waste gas treatment equipment in industrial waste gas, wet scrubber is divided into circulating water wet scrubber, alkali liquid wet scrubber, acid liquid wet scrubber (alias: pickling tower) according to the working principle. According to the material of the tower body, it is divided into FRP wet scrubber, PP wet scrubber and SS wet scrubber. Choose reasonable spray material and spray technology according to the different nature of waste gas.

In fishmeal processing, a large amount of odors are easily generated in the process of cooking, pressing, drying, including crushing and concentration. According to the characteristics of fishmeal odors that are easy to biochemically and easily collect, Feed Machinery proposes a biological spray method, which uses a wet scrubber tower combined with biological fillers. It can effectively control and remove the odor of fish meal.

Parameters

Core Parameters| Capacity | 600-20000 m³/h |

|---|---|

| Material | FRP, PP, SS |

| Pakcing Material | Polyhedral hollow sphere, Pall ring, Packing tube, Activated carbon |

Features

Simple process, low cost, low operating cost, convenient installation and corrosion resistance;

Stable performance, high dust removal efficiency and good desulfurization effect;

Light weight, easy to install, transport and manage;

Especially suitable for odor removal of fish meal odor;

Application

It can be applied to the exhaust gas purification treatment of fish meal plants, shrimp shell meal plants, meat and bone meal plants, etc.

At the same time, it is suitable for all kinds of electronic component material manufacturing industry, chemical industry and experimental sites containing chemical substances, iron and steel metal industry, electroplating and metal surface treatment industry, pickling and grinding, and removal of combustion exhaust gas.

It can effectively purify sulfuric acid mist, hydrogen chloride, hydrogen fluoride, chlorine, ammonia and sulfur oxides, nitrogen oxides, carbon oxides and other gases generated in the production process.

Working Principle

Cases