What are the maintenance work of waste g...

Sludge Dryer

FMSD series disc sludge dryer, different from traditional sludge dryer, adopts horizontal double disc structure, which has the advantages of small footprint, compact structure and larger drying area.

The main shaft adopts seamless steel pipe as the basis to avoid the sharing of broken shafts, and the disc adopts hidden welding seam to prevent the wear and corrosion of the welding seam from sludge, thus greatly prolonging the service life of the dryer.

Features

Seamless steel tube spindle

Use seamless steel tubes to avoid the risk of spindle breakage

Hidden seam design

The disc is designed with hidden welding seam to reduce the wear with the material and prolong the service life

Stainless steel bezel

Stainless steel knife-shaped baffle effectively prevents the material from slipping in the blade and improves the drying efficiency

Application

Sludge

Drying of industrial and municipal sludge

Animal Protein

Production and processing of animal protein feeds such as fish, poultry, pigs, cattle and sheep

Plant Protein

Drying treatment of various vegetable protein powders

Distillers Grains

The wet distiller's grains produced in the brewing process are dried and processed

Working Principle

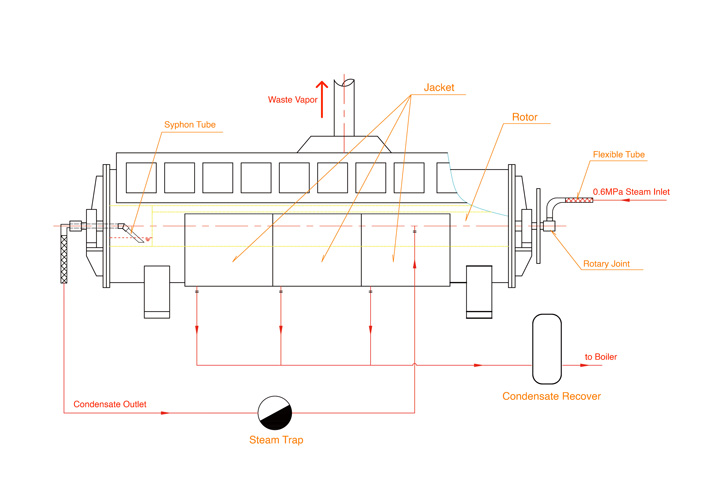

FMSD series sludge dryer adopts saturated steam as heat source (rated steam pressure 0.6MPa), which belongs to indirect steam dryer. It is mainly heated by the main shaft, and can also be heated through the interlayer of the outer casing. The spindle speed is slow, usually 10 to 12 rpm. The material is slowly transferred from the feed end to the discharge end through the pusher system on the outer edge of the blade. The discharge is controlled by a speed-adjustable screw conveyor, which is convenient to adjust the size and speed of the discharge according to the needs.

The heating blades are installed on high-quality seamless steel pipes, and combined with an efficient condensate drainage system, the heating area of the blades can be utilized to the maximum efficiency and a good heat exchange efficiency can be maintained. A stainless steel scraper is installed between the heating blades, which can stir the material, prevent the material from being piled up between the blades, and ensure the complete evaporation of water. The water vapor passes through the stainless steel air collecting hood at the top of the dryer, and is continuously discharged from the machine under the action of the induced draft fan.

Model

| Model | Disc Num | Disc Diameter | Spindle | Motor Power (KW) | Heating Area (m2) | Capacity*1 (MT/h) | Steam*2 (MT/MT Sludge) |

|---|---|---|---|---|---|---|---|

| FMSD-100 | 42 | 1200 | Φ480x25 | 37 | 95.89 | 1 | 0.85/1 |

| FMSD-160 | 45 | 1450 | Φ480x30 | 45 | 157.64 | 1.7 | |

| FMSD-200 | 45 | 1450 | Φ680x35 | 55 | 201.55 | 2.2 | |

| FMSD-260 | 57 | 1700 | Φ680x40 | 75 | 260.73 | 2.8 | |

| FMSD-350 | 59 | 1950 | Φ760x45 | 110 | 350.13 | 3.8 |

Remark*1:The actual treatment amount will vary with the nature of the sludge, Table is for reference

Remark*2:A dryer system equipped with a condensate device can save about 15% of steam. Table is for reference

Document

Get detailed specifications and parameters, Supports on-demand customization, welcome to inquire!

Related Articles

The sludge dryer is a sludge drying equi...

Fish meal dryer is a kind of equipment t...