Purity of Fish Oil Higher And Better

High quality fish oil refining

The fish oil refining solution provided by FeedsMachinery can further reduce the water content, reduce the content of free fatty acid (FFA), and reduce impurities in fish oil, thereby improving the oil quality and prolonging the storage time of fish oil.

Why We Need Fish Oil Refining

Solution for fish oil refining

The raw materials used in fish meal processing machine cannot be guaranteed to be 100% fresh, and during transportation and storage, the raw fish will be spoiled under the action of bacteria and enzymes, resulting in free fatty acids (FFA). Low quality and prone to degradation during storage. So we need a complete solution to reduce free fatty acids (FFA) in fish oil.

FEEDSMACHINERY has been deeply involved in the fishmeal processing industry for many years. It has complete fishmeal processing solutions and a complete set of fishmeal and fish oil refining equipment. For fish oil refining, we provide solutions that can increase the processing capacity to 7000L/h.

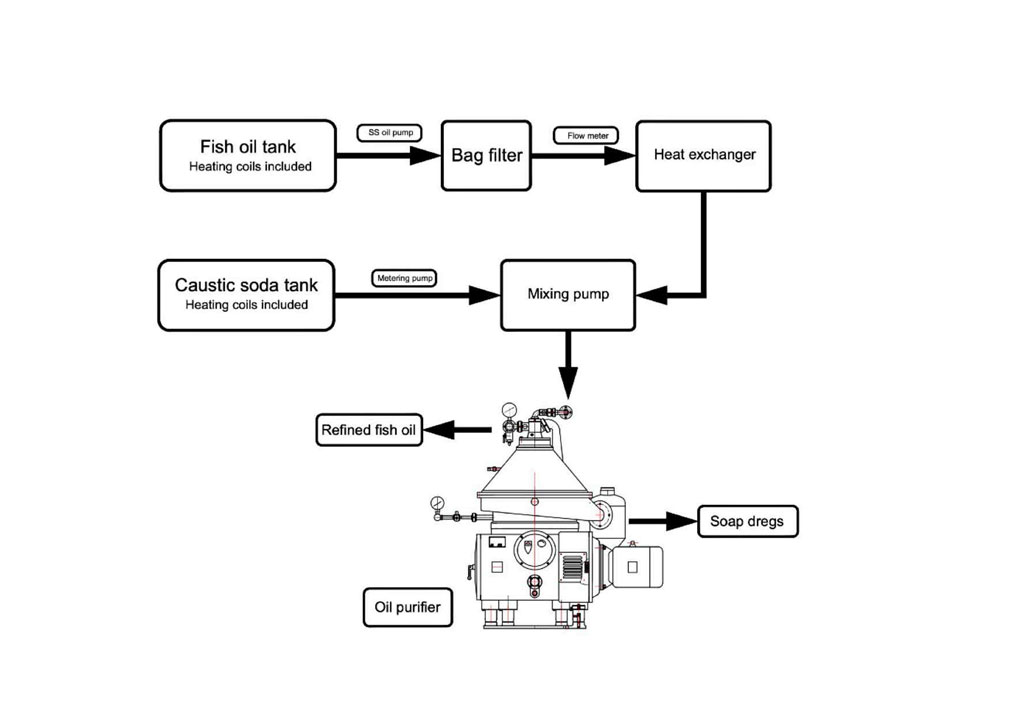

Fish Oil Refining Flow

Working principle of fish oil refining

The fish oil needs to be heated to 90-95 degrees, and after passing through the filter, it is mixed with alkaline water and then enters the disc centrifuge for three-phase separation. In a disc centrifuge, water and saponins are separated from fish oil.

Compared with the horizontal centrifuge, the disc centrifuge has a higher speed and better centrifugal effect. The quality of the refined fish oil is better than that of crude fish oil in terms of sensory and oil quality.

Equipment

Core Equipment For Fish Meal Plant

High quality fish oil refining

The fish oil refining solution provided by FeedsMachinery can further reduce the water content, reduce the content of free fatty acid (FFA), and reduce impurities in fish oil, thereby improving the oil quality and prolonging the storage time of fish oil.

Why We Need Fish Oil Refining

Solution for fish oil refining

The raw materials used in fish meal processing machine cannot be guaranteed to be 100% fresh, and during transportation and storage, the raw fish will be spoiled under the action of bacteria and enzymes, resulting in free fatty acids (FFA). Low quality and prone to degradation during storage. So we need a complete solution to reduce free fatty acids (FFA) in fish oil.

FEEDSMACHINERY has been deeply involved in the fishmeal processing industry for many years. It has complete fishmeal processing solutions and a complete set of fishmeal and fish oil refining equipment. For fish oil refining, we provide solutions that can increase the processing capacity to 7000L/h.

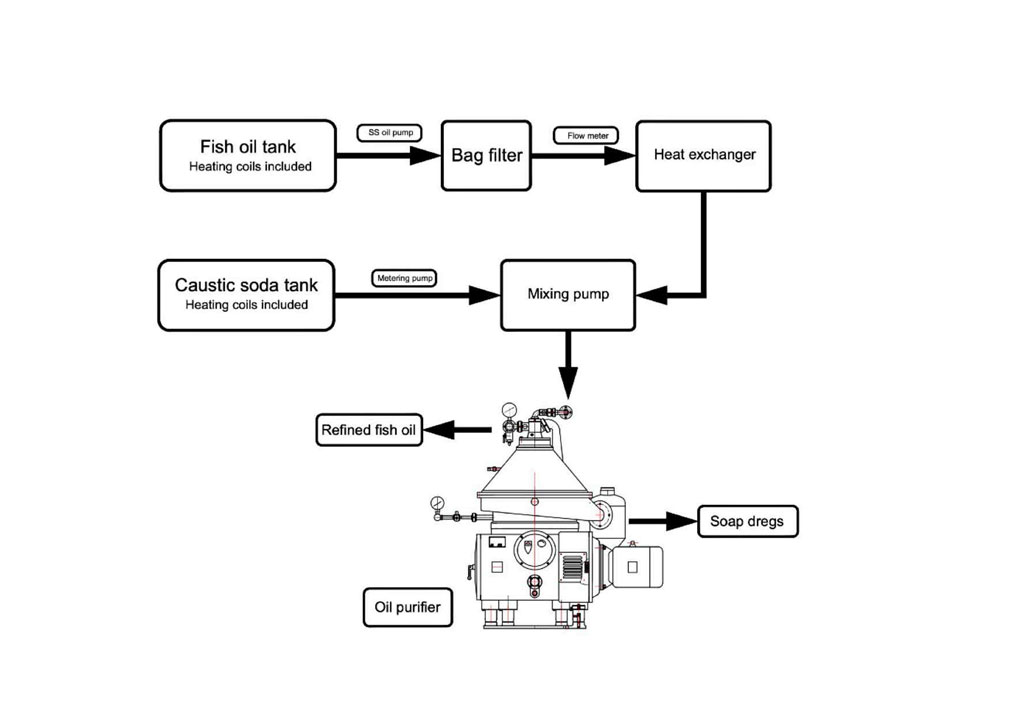

Fish Oil Refining Flow

Working principle of fish oil refining

The fish oil needs to be heated to 90-95 degrees, and after passing through the filter, it is mixed with alkaline water and then enters the disc centrifuge for three-phase separation. In a disc centrifuge, water and saponins are separated from fish oil. Compared with the horizontal centrifuge, the disc centrifuge has a higher speed and better centrifugal effect. The quality of the refined fish oil is better than that of crude fish oil in terms of sensory and oil quality.

Equipment

Core Equipment For Fish Meal Plant