For Fish Meal Industry Odorless Discharge

Odour Control Methods

For fish meal processing tasteless operation

Fishmeal processing uses aquatic product scraps and some small fish and shrimps to make fishmeal for feed through high-temperature steam cooking, pressing, drying, pulverization and other processes. Many links in the production process produce foul gas, which causes serious air pollution.

Based on years of industry experience, FEEDSMACHINERY proposed a comprehensive treatment solution, which effectively solved the problem of waste gas treatment in fishmeal processing plants.

Oxidative combustion deodourization

odour is oxidized and catalytically burned by utilizing the reductive characteristics of most odourous substances. The former can sometimes recover heat, and the instability of production in small and medium-sized fishmeal factories makes heat recovery more difficult; the latter can be operated at low temperature, but the catalyst is easily poisoned , block, use less. It is characterized by high efficiency and high cost.

Adsorption and deodourization

The adsorbent activated carbon, activated clay and other odourous substances are used to adsorb odourous substances, with high deodourization efficiency and low power consumption. It is suitable for waste gas with low odour concentration and no particles, and is not suitable for fish meal production.

Chemical deodourization

Borrowing the chemical unit operation theory, it is suitable for the treatment of waste gas with high concentration of odour pollutants. The technology is mature, the operation is stable, the area is small, and the treatment efficiency is high.

Water dissolving deodourization

Dissolving odourous gas with water to remove odour is characterized by lower investment and operating costs, but the purification effect is not good, and the amount of wastewater produced is too large.

Biological deodourization

According to the characteristics of fishmeal waste gas, combined with the advantages of chemical deodourization and adsorption deodourization, the waste gas pollution of fishmeal processing plants is especially suitable for the technical treatment of biological trickling filtration.That is to improve the deodourization efficiency of fish meal processing, and achieve the purpose of reducing operating costs. The odour components of fish meal production are complex, so this method is applicable.

The characteristics of exhaust gas pollution in fish meal plant:

Easy to collect of fish meal odour

Low concentration of fish meal odour

Good biochemical properties of fish meal odour

Biological Deodourization

For Fish Meal Processing odour control

Biofiltration

Biofiltration is a process in which aerobic microorganisms attach to fixed fillers (peanut shells, wood chips, PU foam, volcanic rocks, etc.) to degrade pollutants through metabolism.

Biofilter

Biofilter is essentially a bioreactor, and microorganisms adhere to the surface of the porous packing medium to form numerous fixed biofilms, providing a huge contact area for gas and biofilm. When the polluted gas passes through the filler medium, the VOCs or odourous compounds in the gas are absorbed by the biofilm and degraded by the biochemical oxidation of microorganisms. The main advantage of biofiltration is that the final product after the pollutants are degraded is not harmful to the environment. Low operating costs and stable operation are also advantages of biological filtration.

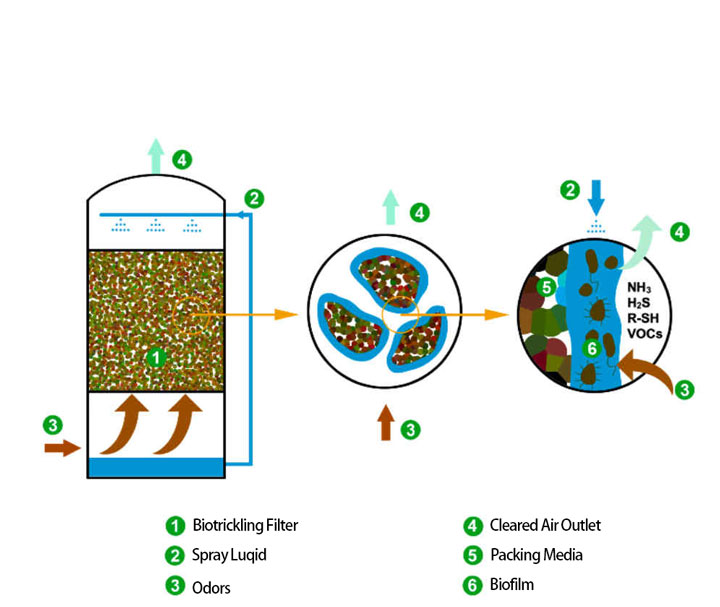

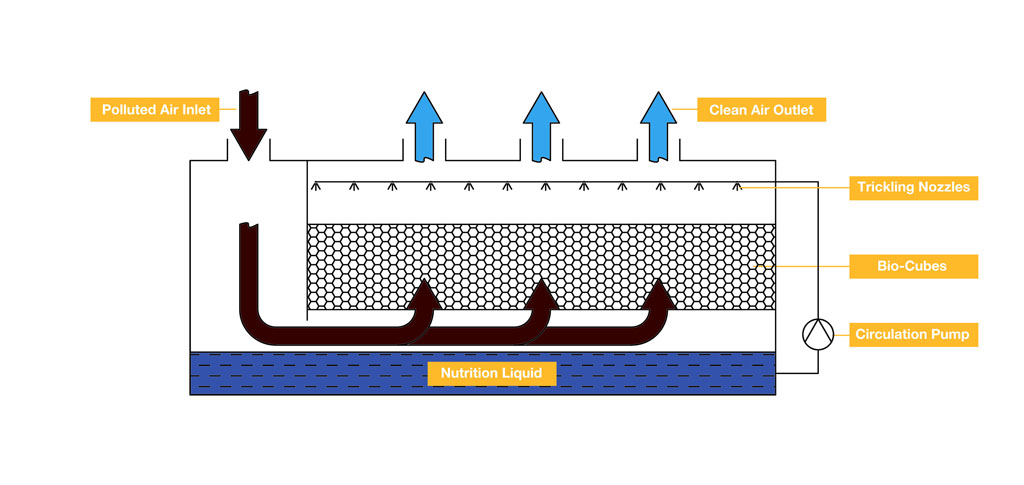

Bio-trickling filter

In the biological trickling filter, while the exhaust gas passes through the fixed biological filler layer, the trickling nozzle continuously sprays liquid into the filler to provide the nutrient solution for the growth of microorganisms. Microorganisms form a biofilm on the surface of the packing and absorb pollutants from the exhaust gas. Through the metabolism of microorganisms, the pollutants are finally degraded. This trickling filtration technology provides more stable growth conditions for microorganisms.

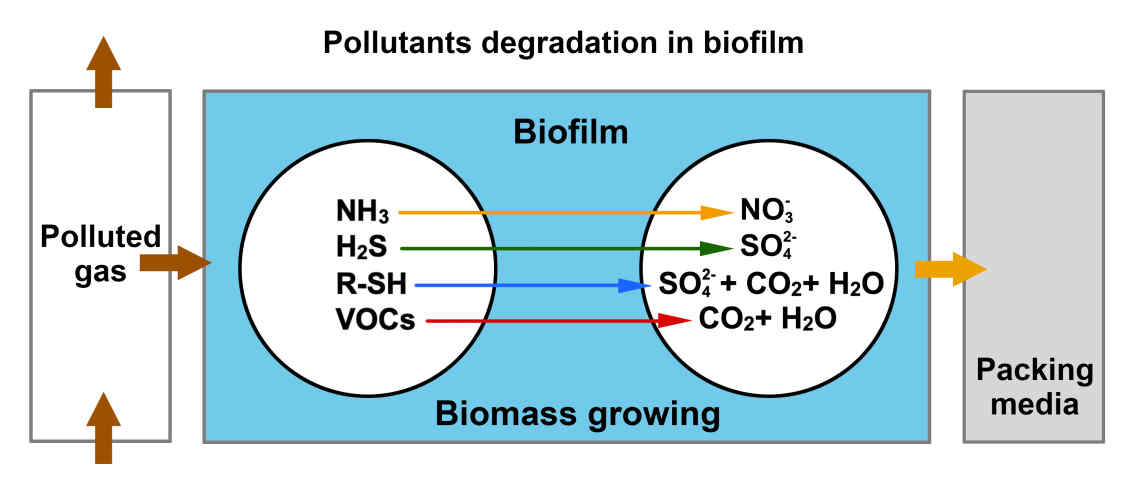

Through the technology of biological filtration, the pollutants in the exhaust gas are degraded by aerobic bacteria into stable products such as CO2, H2O, sulfate, nitrate, etc.

Principle of biological deodourization technology for fish meal processing

Advantages

Biofiltration of fish meal plant

Lower cost of deodorization

Friendly to the environment

No secondary pollution

Up deodorizing efficiency

Process flow

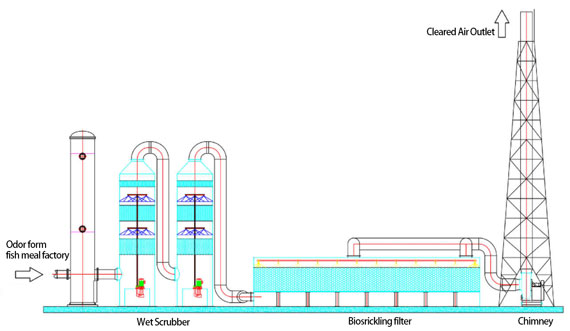

For fish meal processing odour control

Exhaust condenser

The condenser turns most of the water vapor in the exhaust gas into liquid water, which can reduce the volume of the exhaust gas by more than 40% and reduce the subsequent processing load.

Chemical Spray Tower

The spray scrubber absorbs ammonia gas and hydrogen sulfide gas in the exhaust gas by adding different absorbing liquids to reduce the load of biological trickling filtration.

Bio-trickling Filter

Using the VOCs in the exhaust gas as the energy and carbon source of the microorganisms, through the metabolism of the microorganisms, the trimethylamine, ethanethiol, ammonia, hydrogen sulfide and other substances in the exhaust gas are degraded into CO2H2O, sulfate, nitrate and other non-toxic and harmless substances of small molecules.

Engineering case

For fish meal processing biological deodorization

Equipment

Core Equipment For Fish Meal Plant